Encapsulating Parts Through Reaction Injection Molding (RIM): Matching Material to Application Requirements

Most engineers default to mechanical fasteners or adhesives when integrating components into larger...

By: Paul Steck on Oct 8, 2025 10:35:51 AM

Engineers face a persistent challenge: how do you protect sensitive components without compromising design freedom, adding significant weight, or inflating production costs? The answer often lies in encapsulation—but the method you choose determines whether you solve the problem or create new ones.

Reaction Injection Molding offers encapsulation capabilities that conventional processes simply cannot match. The combination of low processing temperatures, minimal molding pressure, and material versatility creates opportunities to protect everything from delicate circuit boards to structural metal reinforcements within a single molded part.

Conventional injection molding operates at temperatures exceeding 400°F with pressures reaching 20,000 psi. These extreme conditions make encapsulating temperature-sensitive electronics nearly impossible. Even ruggedized components risk damage from thermal stress or pressure-induced flexing during the molding cycle.

Potting compounds and conformal coatings provide protection but add manufacturing steps, increase labor costs, and often require lengthy cure times. More critically, they limit design integration—you're protecting components rather than building them into the structural architecture of your product.

RIM changes this equation entirely.

RIM processing occurs at temperatures between 90-105°F with molding pressures of only 50-150 psi. This gentle process allows direct encapsulation of components that would fail in traditional molding environments. Circuit boards, sensors, RFID chips, wire harnesses, and battery assemblies can be positioned in the mold and completely surrounded by thermoset polyurethane as it cures.

The polyurethane itself contributes to protection. Unlike thermoplastics that can creep or relax under sustained load, thermoset materials maintain dimensional stability across wide temperature ranges. Chemical resistance can be engineered into the material formulation, providing barrier protection against solvents, oils, and corrosive substances without secondary coatings.

Medical device manufacturers face stringent requirements for both environmental protection and biocompatibility. Diagnostic instruments often integrate sensitive optical sensors, precision electronics, and complex fluidic systems—all of which must function reliably across varied clinical environments.

Consider a point-of-care diagnostic device that must withstand daily cleaning with hospital-grade disinfectants while maintaining calibration accuracy. The internal electronics require complete environmental sealing, but the device also needs integrated mounting points, cable management features, and user interface elements.

RIM encapsulation allows the entire assembly—circuit boards, sensors, and cable connections—to be molded into a single housing. The low processing temperature preserves component integrity while the polyurethane creates a seamless barrier against fluid ingress. Mounting bosses, alignment features, and structural ribs can be molded integrally, eliminating secondary assembly operations that might compromise the environmental seal.

Industrial applications demand protection from more aggressive threats. Equipment operating in chemical processing plants, offshore platforms, or heavy manufacturing environments faces sustained exposure to corrosive chemicals, extreme temperatures, and physical abuse that would quickly degrade standard enclosures.

A chemical processing control module illustrates the challenge. The electronics must survive direct exposure to industrial solvents while maintaining EMI shielding and managing heat dissipation from power components. The enclosure requires multiple cable entry points, each a potential failure point for environmental sealing.

RIM encapsulation enables a different approach. Rather than building a sealed enclosure with gasketed cable entries, the entire assembly can be overmolded. Cable harnesses enter the mold with the circuit board, and the polyurethane flows around every surface, creating intimate contact that blocks moisture and chemical infiltration. The material's inherent chemical resistance—particularly in formulations like Poly-DCPD—provides protection that doesn't degrade over time like coatings or gaskets.

Aerospace applications demand maximum protection at minimum weight. Avionics components must survive shock, vibration, extreme temperature cycling, and altitude-induced pressure differentials while adding as little mass as possible to the aircraft.

Traditional approaches use machined aluminum housings with complex internal mounting structures to isolate electronics from vibration. This provides protection but adds significant weight. Potting compounds reduce vibration transmission but complicate repairs and add processing steps.

RIM encapsulation allows structural integration. Circuit boards can be suspended within the molded part using minimal support structures, with the polyurethane providing both vibration dampening and environmental protection. The resulting assembly weighs substantially less than a machined housing while maintaining mechanical integrity across the operational temperature range from -65°F to 200°F.

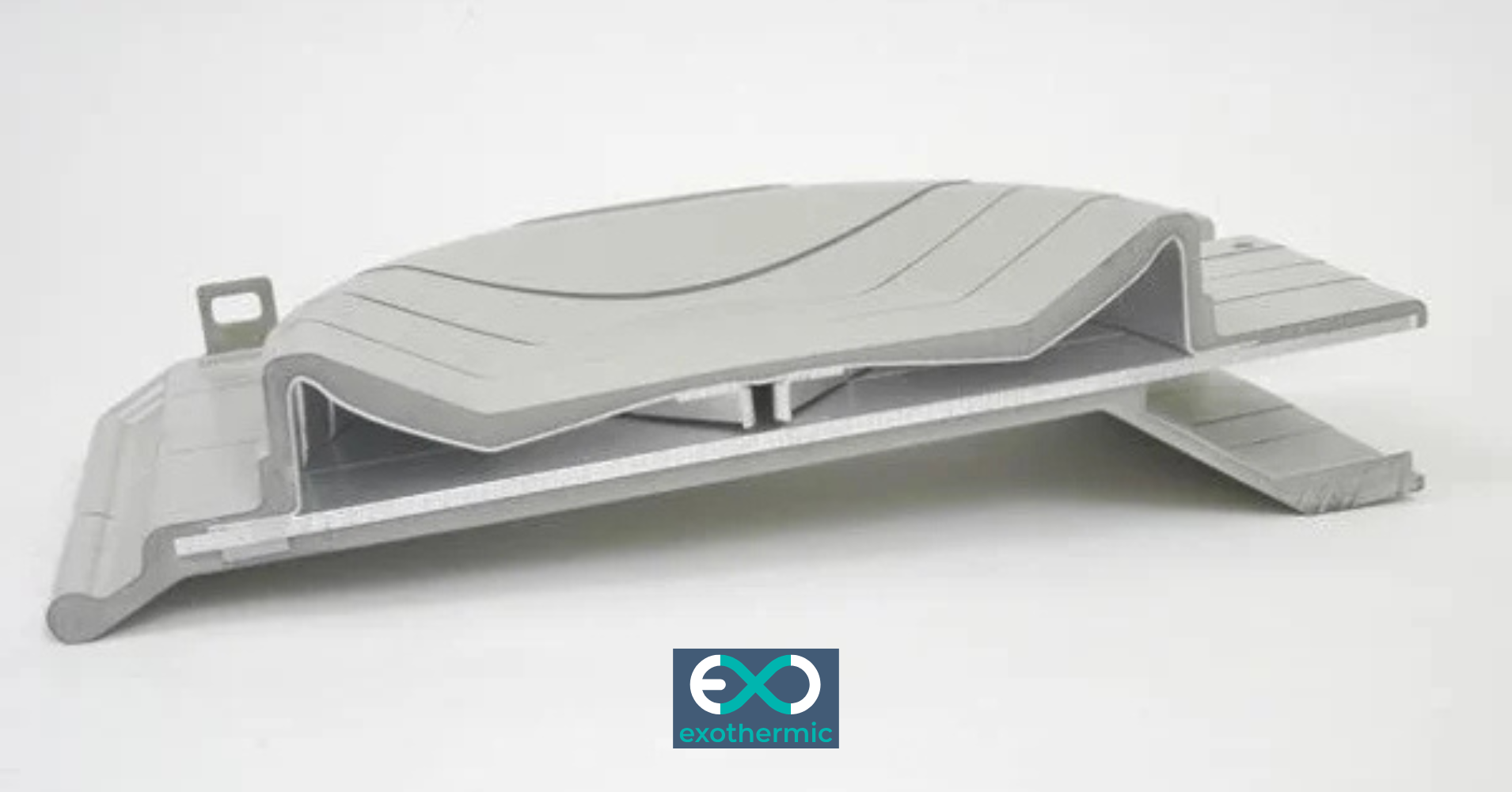

Encapsulation isn't limited to protecting sensitive components. Engineers increasingly use RIM to create composite structures by encapsulating metal reinforcements, carbon fiber inserts, or even air cavities for specific functional purposes.

A structural panel requiring high rigidity but low weight might use aluminum extrusions as the load-bearing core, with RIM polyurethane molded around them. The polyurethane bonds to the metal, creating a unified structure that distributes loads more effectively than mechanical fasteners while eliminating corrosion at metal-to-metal interfaces.

Air encapsulation serves distinct purposes—creating flotation in marine applications, providing thermal insulation in temperature-critical assemblies, or reducing acoustic transmission in noise-sensitive equipment. The molding process allows precise control over cavity geometry and wall thickness, enabling engineers to optimize these properties for specific applications.

Successful encapsulation requires planning from the initial design phase. Component placement must account for material flow patterns during molding. Critical dimensions may need to be machined post-molding rather than relying solely on as-molded accuracy. Thermal expansion mismatches between encapsulated components and the surrounding polyurethane need evaluation across the operational temperature range.

However, these considerations are manageable when working with experienced RIM manufacturers who understand both the material science and the application requirements. The design freedom RIM provides—variable wall thickness, complex geometries, integrated features—typically outweighs the additional planning required.

RIM encapsulation makes most sense for production volumes between 100-5000 parts annually where conventional injection molding tooling costs can't be justified, but hand assembly or potting operations become prohibitively labor-intensive. The technology excels when you need to protect sensitive components, integrate multiple parts into a single assembly, or combine environmental protection with structural function.

For applications demanding protection that conventional processes can't deliver, encapsulation through RIM offers an engineering solution worth evaluating.

Most engineers default to mechanical fasteners or adhesives when integrating components into larger...

When engineers evaluate materials for structural applications, the question "Is it stronger than...

When engineers face challenging part requirements—large housings, impact-resistant components, or...