The Advantage of RIM for Large Molded Plastic Parts

When engineers must manufacture large plastic parts with complex geometries, variable wall...

By: Paul Steck on Aug 5, 2025 8:00:00 AM

When engineers need to produce large plastic parts, they often face a frustrating trade-off: accept design limitations or pay premium tooling costs. This challenge becomes particularly acute for automotive body panels, industrial enclosures, and medical equipment housings where complex geometries and advanced material properties are essential.

The question isn't whether you can make large parts with various processes—it's whether you can make them well without breaking your budget or compromising your design intent.

Traditional manufacturing processes impose significant constraints on large part design. Thermoforming limits you to relatively simple geometries with uniform wall thickness. Injection molding requires expensive steel tooling that can cost hundreds of thousands of dollars. Sheet metal fabrication forces you to design around welding and assembly constraints.

These limitations become especially problematic when you need features like varying wall thickness, integrated structural elements, or the ability to encapsulate other components. A medical equipment housing might require thin walls for weight reduction but thick sections for mounting points. An automotive panel needs complex curves with integrated attachment features.

Reaction Injection Molding eliminates most of these design constraints while keeping tooling costs manageable for production volumes under 5,000 parts annually.

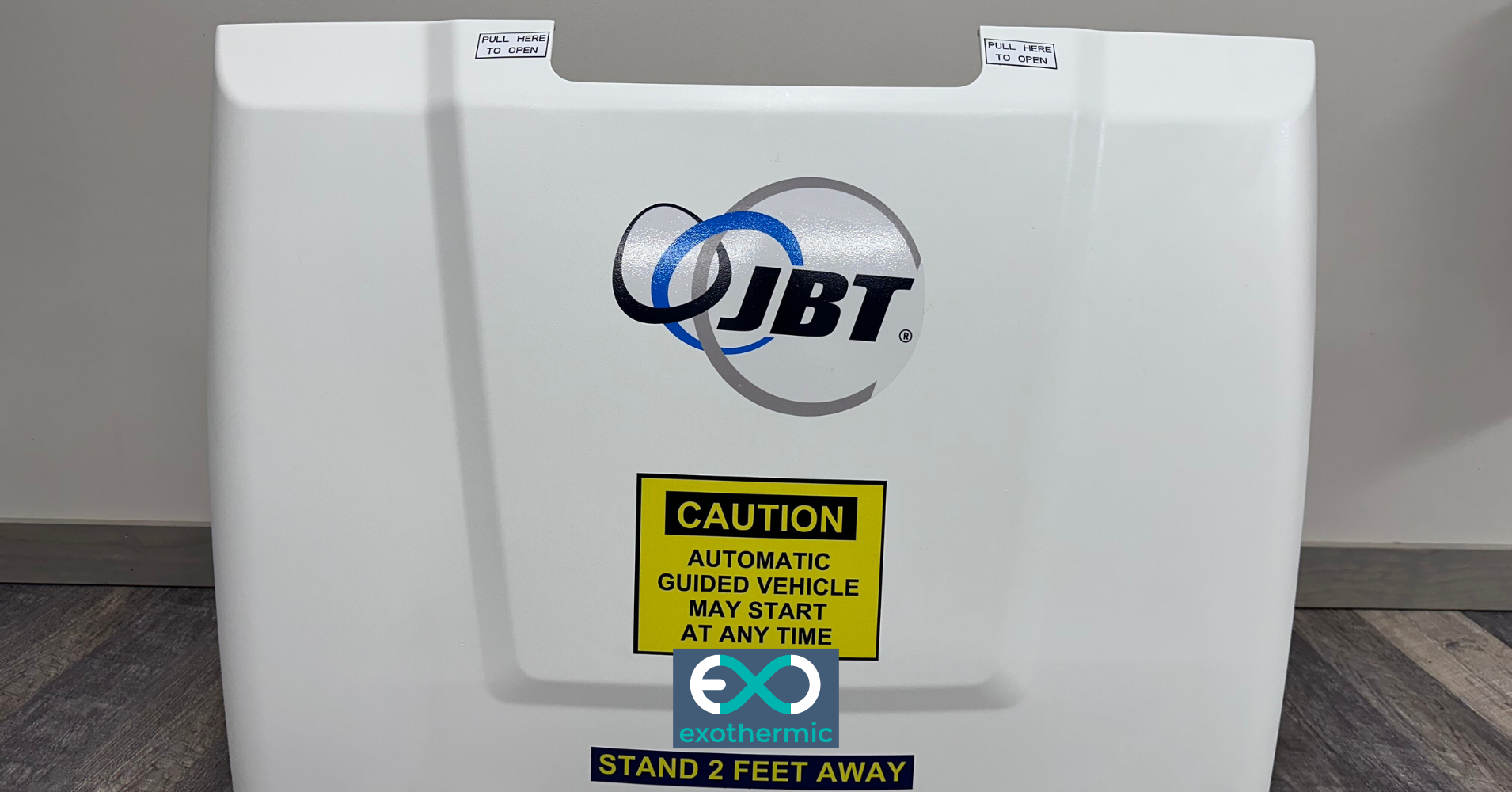

.jpg?width=800&height=600&name=JBT%20Shield%20Straight%20Front%20(1).jpg)

The low-viscosity liquid components used in RIM flow easily through large mold cavities, filling complex geometries completely. Unlike thermoplastics that require high pressure and temperature, RIM operates at molding pressures of only 50-150 psi and temperatures around 90-105°F.

This low-pressure process enables several key advantages for large parts. Wall thickness can vary significantly within the same part—from 0.125 inches to over 1 inch where structural support is needed. Complex internal features like ribs, bosses, and mounting points can be molded directly into the part, eliminating secondary assembly operations.

The aluminum tooling used for RIM costs roughly half that of comparable steel injection molding tools. For a large automotive panel, this difference can mean $200,000 in tooling savings while maintaining production-quality surface finish.

Thermoforming appears attractive for large parts due to low tooling costs, but the design limitations quickly become apparent. Sheet forming cannot create varying wall thickness or internal features. Any mounting bosses, ribs, or complex geometry must be added as secondary operations.

Consider an industrial equipment enclosure that needs integrated EMI shielding, multiple mounting points, and wire management features. Thermoforming would require the base shell plus numerous secondary components bonded or mechanically fastened together. RIM can integrate all these features into a single molded part.

Material selection also favors RIM. While thermoforming is limited to available sheet materials, RIM can utilize advanced polyurethane and polyolefin systems optimized for specific performance requirements like chemical resistance, impact strength, or flame retardancy.

Production volume drives the economic decision between processes. Thermoforming becomes cost-effective at very low volumes where tooling speed matters more than part complexity. Injection molding requires high volumes to justify the tooling investment.

RIM occupies the sweet spot between 100 and 5,000 parts annually, where design complexity, material performance, and tooling economics align. A medical device housing requiring 1,500 units per year benefits from RIM's design freedom without the tooling penalty of injection molding.

Modern RIM materials like Poly-DCPD offer properties that expand what's possible in large part applications. These materials provide exceptional chemical resistance, high-temperature stability, and impact strength while being 7-10% lighter than traditional alternatives.

For automotive applications, this means body panels that resist road chemicals while maintaining structural integrity. Medical equipment housings can withstand aggressive cleaning agents while protecting sensitive electronics. Industrial enclosures maintain dimensional stability in harsh operating environments.

The combination of design flexibility and advanced materials opens possibilities that other processes cannot match. Electronic components can be encapsulated directly during molding for environmental protection. Metal reinforcements can be molded in place for localized strength. Complex internal geometries create parts that function as both structure and aesthetic surface.

An automotive interior panel might integrate HVAC ducting, wire routing channels, and mounting points for multiple components—all molded as a single piece. This level of part consolidation reduces assembly time and potential failure points while improving overall system performance.

When evaluating large part manufacturing options, consider your design requirements first. If you need uniform wall thickness and simple geometry, thermoforming might suffice. If production volumes exceed 5,000 parts annually and you can accept design constraints, injection molding could work.

But if you need design freedom, advanced material properties, and reasonable tooling costs for moderate production volumes, RIM delivers capabilities that other processes cannot match. The question becomes not whether you can make large parts with RIM, but whether you can afford to limit your design potential with other processes.

The engineering reality is straightforward: RIM eliminates the traditional trade-offs between design complexity, material performance, and economic viability for large parts in the 100-5,000 unit production range.

When your application demands more than what conventional processes can deliver, RIM provides the design freedom to create what you actually need.

When engineers must manufacture large plastic parts with complex geometries, variable wall...

Industrial designers face a variety of material choices when creating products, including metal,...

In today's manufacturing landscape, finding the proper process for custom parts can be challenging....