Advanced Ballistic Materials Manufacturing

NEOZANT™ Solutions Outperforming Kevlar

Defense contractors and law enforcement agencies face a critical challenge: traditional aramid fibers like Kevlar degrade in harsh environments while adding unnecessary weight to protective systems. Our advanced NEOZANT™ ballistic materials deliver superior protection at 26% less weight, maintaining full performance from -100°F to 250°F where conventional materials fail.

Through strategic partnership with Extremis Systems, we provide comprehensive ballistic solutions from prototype development through production volumes up to 5,000 units annually. Whether your application requires custom manufacturing or distribution of proven ballistic components, our engineering team evaluates each project to determine the optimal approach for your performance requirements.

Revolutionary Material Performance That Exceeds Defense Standards

NEOZANT™ ballistic composites represent a fundamental advancement in protective material science. Built on Nobel Prize-winning Ring Opening Metathesis Polymerization (ROMP) chemistry, these materials achieve ballistic performance metrics that traditional aramid and polyethylene systems cannot match.

Testing validates 260% greater strength-to-weight ratio compared to equivalent Kevlar systems when measured by NIJ 0106.01 backface deformation standards. Where aramid fibers absorb moisture and degrade over time, NEOZANT™ maintains structural integrity after saltwater immersion and extreme temperature cycling. The material's superior impact energy dissipation distributes force outward rather than concentrating trauma, reducing behind-armor blunt force injuries.

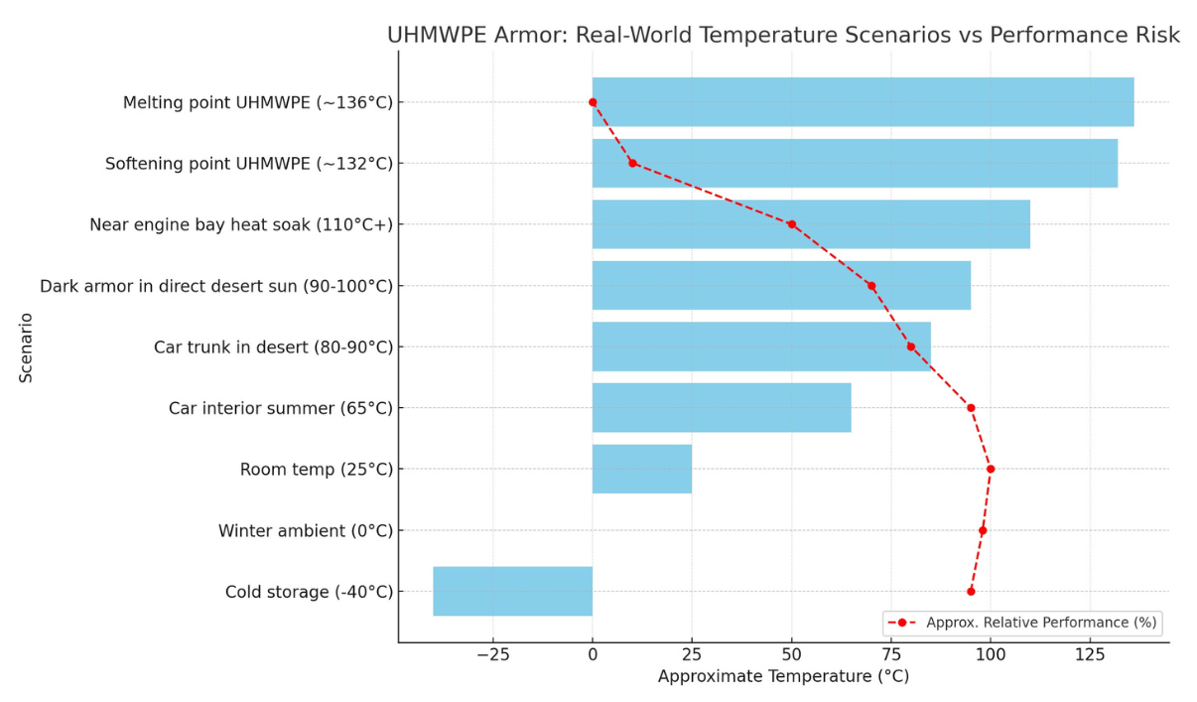

Temperature resilience proves critical in real-world applications. While polyethylene systems lose structural integrity above 160°F, NEOZANT™ composites maintain full ballistic performance across operational ranges from arctic conditions to desert environments. This thermal stability eliminates performance degradation concerns that compromise traditional materials in extreme climates.

Custom Manufacturing for Complex Ballistic Applications

When your ballistic protection requirements demand custom engineering, our Reaction Injection Molding capabilities enable geometries impossible with traditional manufacturing methods. The process accommodates complex shapes with wall thickness variations from 0.125" to 1.125" within single components, eliminating assembly complexity while maintaining ballistic integrity.

Our manufacturing approach leverages NEOZANT™'s water-like viscosity for rapid composite infusion - processing 10 times faster than conventional epoxy systems. This efficiency enables production of large ballistic panels, curved armor sections, and integrated protective housings without autoclave requirements or hydraulic pressing constraints.

Component integration through encapsulation technology allows direct molding of ballistic materials around electronics, structural members, or mounting hardware. This capability proves valuable for applications requiring integrated protection systems where traditional layered approaches create vulnerability points at component interfaces.

Quality control follows aerospace standards with comprehensive testing protocols.

Strategic Distribution of Proven Ballistic Solutions

For applications where proven ballistic components meet your performance requirements, we provide efficient distribution of Extremis Systems' validated products. This approach accelerates deployment timelines while ensuring field-tested reliability for critical protection applications.

Helmet systems, body armor panels, and vehicle protection components benefit from Extremis Systems' extensive validation testing and certification processes. Our distribution network ensures rapid availability of these proven solutions while providing technical support for integration into your specific applications.

Engineering consultation remains available throughout the distribution process. Our technical team assists with component selection, integration planning, and performance optimization to ensure delivered products meet your exact operational requirements.

Engineering Partnership Approach to Ballistic Protection

Project evaluation begins with a comprehensive requirements analysis. Our engineering team assesses ballistic performance targets, environmental conditions, weight constraints, and geometric requirements to determine whether custom manufacturing or distribution best serves your application needs.

For custom applications, we provide complete design support from concept through production. This includes material selection optimization, manufacturing process development, and comprehensive testing validation. Our ISO 9001:2015 certified processes ensure consistent quality across all production volumes.

Distribution projects receive equal engineering attention. We verify component compatibility, provide integration guidance, and coordinate delivery schedules to support your project timelines. Technical documentation and certification data accompany all distributed products to streamline your qualification processes.

Long-term partnership extends beyond initial delivery. We maintain technical support relationships, monitor performance feedback, and provide ongoing consultation for product optimization or application expansion. This collaborative approach ensures your ballistic protection systems continue meeting evolving operational requirements.

Ready to evaluate how NEOZANT™ ballistic materials can enhance your protection systems? Contact our engineering team to discuss your specific performance requirements and determine the optimal manufacturing or distribution approach for your application.