Sustainability in Manufacturing: How RIM DCPD Materials are Creating a Greener Future

In today's climate-conscious world, manufacturers are increasingly seeking sustainable alternatives...

By: Paul Steck on Sep 9, 2025 8:00:00 AM

Marine engineers face a brutal reality when selecting materials for boat interior components. Traditional materials either corrode rapidly, crack under stress, or fail when exposed to the constant moisture and temperature fluctuations found in marine environments. After decades of testing various solutions, one material consistently outperforms alternatives for larger marine equipment enclosures: Poly-DCPD (Polydicyclopentadiene).

Engineers designing marine equipment enclosures confront multiple simultaneous stressors. Salt spray creates corrosive conditions that attack most metals and degrade many plastics. Constant humidity promotes mold growth and material degradation. Temperature swings from hot engine compartments to cold overnight conditions create expansion and contraction cycles that crack rigid materials.

UV radiation from reflected sunlight off water surfaces proves particularly destructive, breaking down polymer chains in conventional plastics. Vibration from engines and wave action creates fatigue stress that slowly weakens components over time. These factors combine to create one of the harshest operating environments for manufactured components.

Poly-DCPD addresses these challenges through its unique molecular structure and processing characteristics. The material demonstrates exceptional chemical resistance to salt water, hydraulic fluids, and cleaning chemicals commonly used in marine maintenance. Unlike fiberglass, which can develop osmotic blisters when water penetrates the resin matrix, Poly-DCPD maintains its integrity even after prolonged saltwater exposure.

The material's low water absorption rate prevents the swelling and dimensional changes that plague other polymer systems in humid environments. This stability proves critical for equipment enclosures that must maintain precise fits and sealing surfaces over years of service.

Temperature resistance represents another key advantage. Poly-DCPD maintains its mechanical properties across the temperature range typically encountered in marine applications, from freezing overnight conditions to hot engine compartments reaching 180°F. This thermal stability eliminates the cracking and warping issues common with other materials.

Marine equipment faces constant mechanical stress from wave action, dock impacts, and crew movement. Poly-DCPD's exceptional impact strength and fracture toughness protect equipment enclosures from damage that would crack or shatter conventional materials.

The material's ability to absorb energy during impact events makes it particularly valuable for helm consoles, instrument panels, and equipment cabinets that must withstand both intentional loads and accidental impacts. This toughness translates directly to reduced maintenance costs and improved reliability in service.

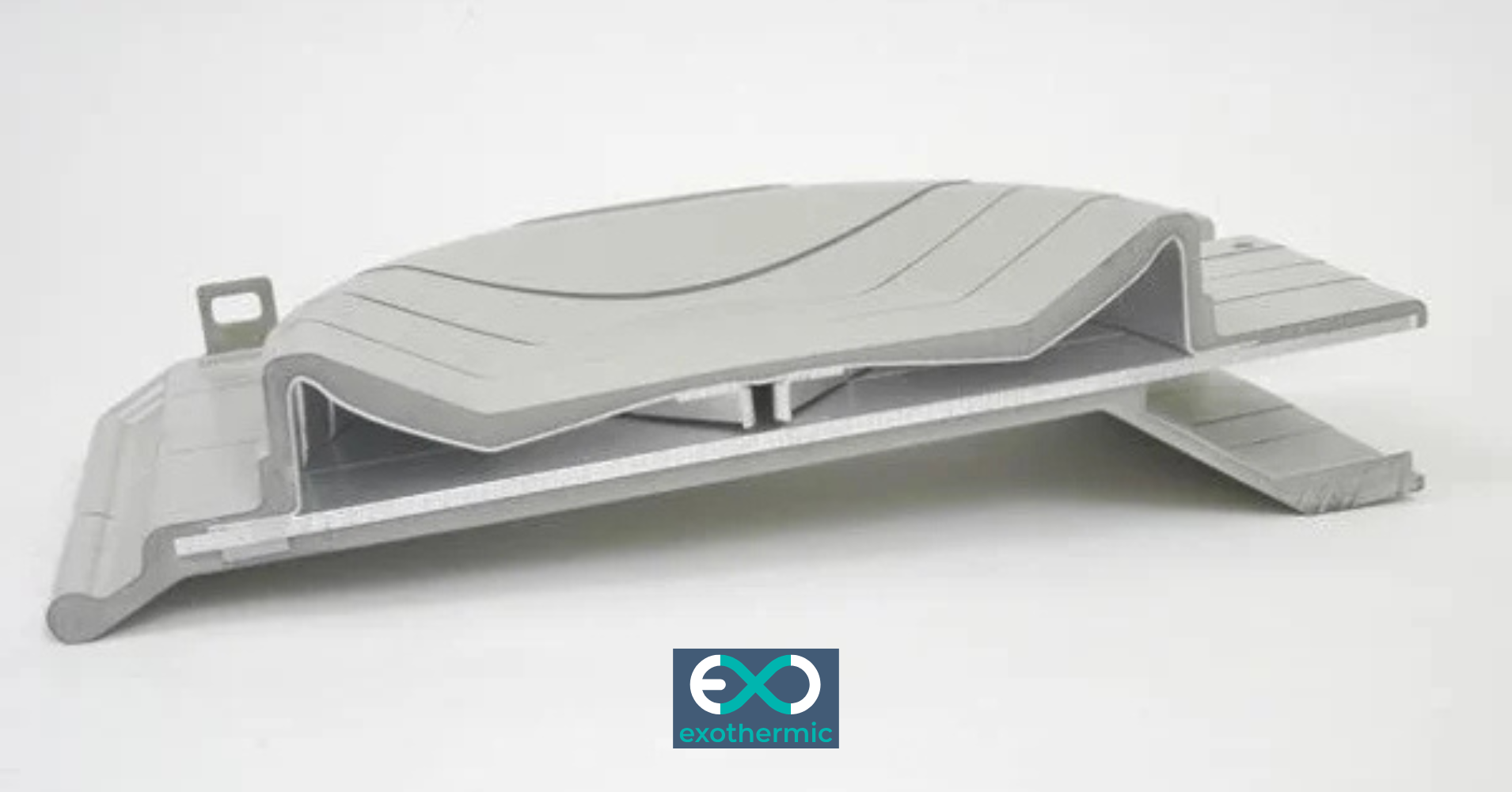

The RIM (Reaction Injection Molding) process used with Poly-DCPD offers significant advantages for manufacturing large marine components. The low-pressure molding process allows creation of parts with varying wall thicknesses, enabling engineers to optimize strength where needed while maintaining reasonable weight.

Complex geometries become feasible without expensive secondary operations. Features like integrated mounting bosses, cable routing channels, and sealing surfaces can be molded directly into the part. This design flexibility allows engineers to consolidate multiple components into single assemblies, reducing assembly time and potential leak paths.

Large parts that would be prohibitively expensive to mold in traditional thermoplastics become economically viable through RIM processing. Helm consoles measuring several feet in each dimension can be produced as single pieces, eliminating joints and seams where water could penetrate.

When evaluating materials for marine equipment enclosures, engineers should prioritize chemical resistance, dimensional stability, and long-term UV resistance. Poly-DCPD excels in all these areas while offering processing advantages that reduce manufacturing costs for complex, large components.

The material's proven track record in demanding marine applications provides confidence for engineers specifying components that must perform reliably in harsh saltwater environments. From fishing vessel electronics enclosures to luxury yacht helm consoles, Poly-DCPD consistently delivers the durability and performance marine applications demand.

For marine engineers facing the challenge of creating reliable equipment enclosures, Poly-DCPD represents a material solution that addresses the unique stressors of the marine environment while offering the processing flexibility needed for complex, large components.

In today's climate-conscious world, manufacturers are increasingly seeking sustainable alternatives...

For manufacturers using Reaction Injection Molding (RIM), understanding UL 94 standards is crucial...

When engineers evaluate materials for structural applications, the question "Is it stronger than...