Why We're Called Exothermic

When people first hear our company name, they often wonder - why Exothermic? The fascinating...

Engineering innovation increasingly demands geometries that challenge conventional manufacturing wisdom. Complex curves, integrated reinforcement structures, multi-functional part consolidation, and variable cross-sections represent the frontier where RIM molding demonstrates its technical superiority over traditional manufacturing processes.

These capabilities enable engineers to optimize part performance rather than compromise designs to accommodate manufacturing limitations.

The low-viscosity chemistry of RIM materials provides exceptional flowability that enables filling intricate mold details impossible to achieve with molten thermoplastics. Viscosities ranging from 500 to 1500 centipoise enable the complete filling of thin sections, sharp details, and complex internal geometries while maintaining consistent wall thickness throughout the part.

This flowability enables designers to create parts with internal channels for wire routing, complex surface textures for improved grip or aesthetics, and sharp detail resolution that maintains consistency across production runs without the flow marks or incomplete filling common in injection molding of complex parts.

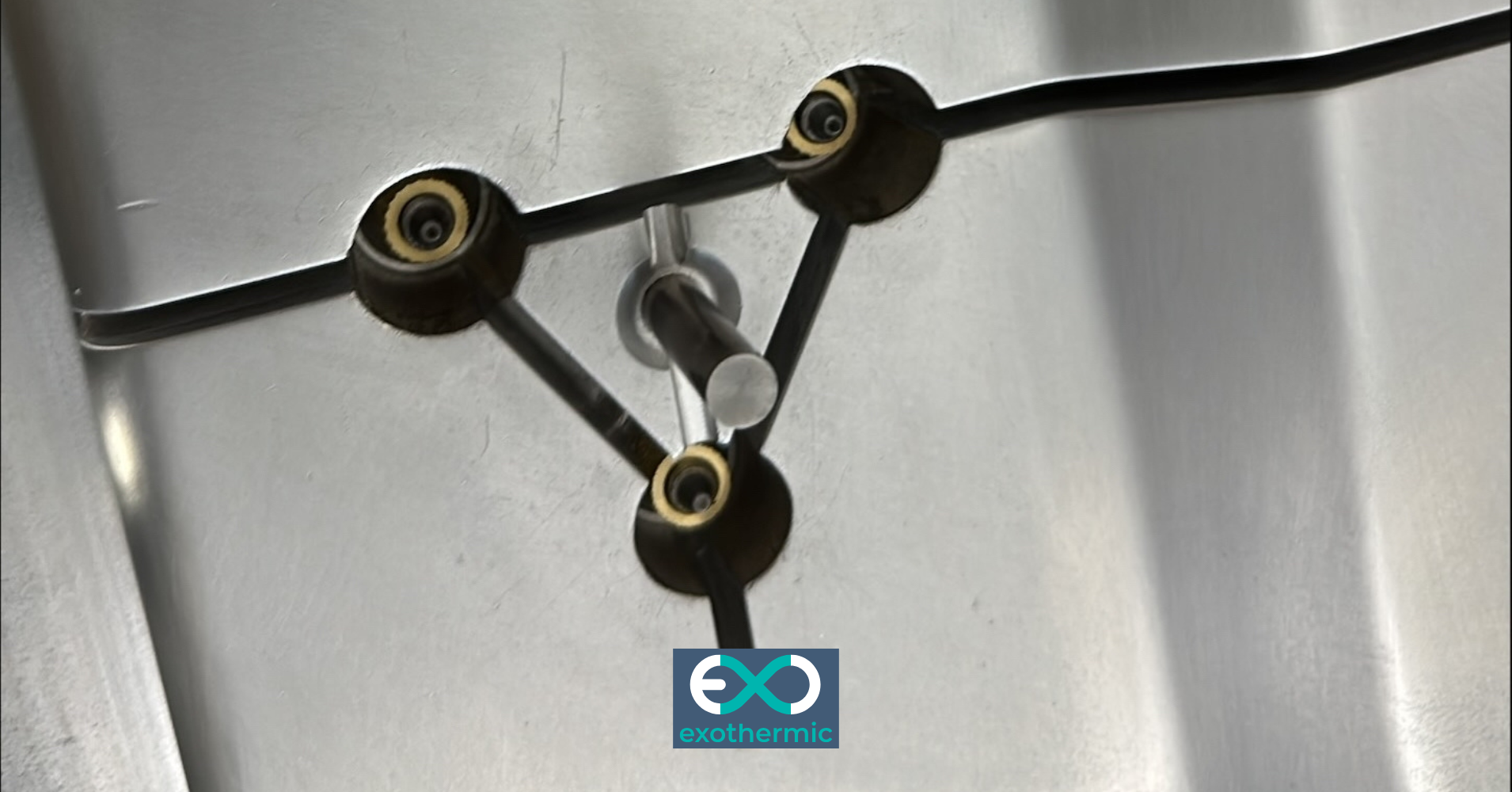

Part consolidation becomes particularly powerful when combining RIM's geometric capabilities with its encapsulation properties. A recent aerospace application illustrates this advantage dramatically. The original design consisted of a 12-piece welded aluminum assembly including mounting brackets, wire routing guides, and electromagnetic shielding panels.

Engineering analysis identified opportunities to consolidate these components into a single RIM-molded part that incorporated mounting bosses, integrated wire routing channels, and encapsulated metal reinforcement plates. The consolidated design reduced total weight by 35% compared to the original assembly while eliminating 11 potential failure points and reducing assembly time from 45 minutes to a simple bolt-on installation.

The ability to vary wall thickness strategically allows engineers to optimize material placement for specific loading conditions rather than accepting the uniform thickness constraints imposed by injection molding.

Thick sections provide structural strength where mounting stresses concentrate, while thin sections minimize weight in non-critical areas. This optimization approach often results in parts that outperform uniform-thickness alternatives while using 20-30% less material overall.

Finite element analysis can guide this optimization process, identifying optimal thickness distributions that RIM molding can achieve but injection molding cannot economically produce.

Complex internal geometries represent another area where RIM excels. Internal channels for fluid flow, wire routing, or cooling can be molded directly into parts using dissolvable cores or complex tooling that would be prohibitively expensive for injection molding.

A medical device application required internal channels for reagent flow combined with integrated optical components and complex external geometry for ergonomic handling. RIM molding produced this part in a single operation, whereas alternative approaches would have required the assembly of multiple components, potentially introducing leak paths and optical misalignment issues.

RIM's compatibility with glass fiber reinforcement extends geometric capabilities even further. Localized reinforcement placement allows engineers to tailor strength characteristics to specific stress patterns, creating parts that perform like engineered composites while maintaining the surface finish quality of unreinforced plastics.

Glass mat can be placed selectively in high-stress areas while leaving cosmetic surfaces unreinforced for optimal appearance. This selective reinforcement approach enables parts with strength-to-weight ratios approaching those of aluminum, while maintaining the design freedom and corrosion resistance of plastics.

The encapsulation of metal components within RIM parts creates opportunities for geometric complexity that would be impossible through conventional assembly methods. Threaded inserts, mounting brackets, heat dissipation elements, and structural reinforcements can be positioned precisely during molding and become integral parts of the finished component.

A recent industrial application required mounting points capable of withstanding 10,000-pound loads while maintaining precise positioning tolerances. RIM encapsulation of steel reinforcement plates provided the required strength while enabling complex external geometry that would have been impossible to achieve through welding or mechanical assembly.

Surface texture complexity represents another advantage of RIM molding. Deep textures, sharp details, and complex patterns can be reproduced consistently because the low-pressure molding process doesn't distort fine mold features.

Leather grains, technical patterns, and even text can be molded with definition that approaches injection molding quality while accommodating the geometric complexity that injection molding cannot handle. This capability enables single-process production of parts that would require secondary texturing operations with other manufacturing methods.

Undercut geometry capabilities depend on material selection, but elastomeric RIM formulations can accommodate significant undercuts without requiring complex tooling features.

This flexibility enables snap-fit connections, integrated clips, and other functional features that would require side actions or multiple tooling operations with rigid materials. The combination of geometric complexity and functional integration often results in part designs that would be impossible to produce economically through any other single manufacturing process.

The design freedom enabled by RIM molding encourages engineers to think beyond traditional part boundaries and consider optimal functional integration.

Rather than designing parts to fit available manufacturing processes, RIM enables designing parts to optimize performance and then selecting tooling approaches that support the optimal design.

This design-first approach often leads to innovative solutions that provide competitive advantages through superior functionality, reduced weight, improved reliability, or enhanced user experience.

When people first hear our company name, they often wonder - why Exothermic? The fascinating...

The conversation usually starts the same way. Quality is slipping. Lead times keep stretching....

When engineers first encounter polydicyclopentadiene (Poly-DCPD) molding, one of the most frequent...