Encapsulation in RIM Molding: Beyond Surface Protection

When engineers think about protecting sensitive components or enhancing structural integrity, they...

By: Paul Steck on Nov 11, 2025 8:00:01 AM

The heat problem in modern electronics keeps getting worse. As processors become more powerful and components pack tighter into smaller spaces, managing thermal buildup has become a critical design challenge. For engineers designing electronic enclosures, the traditional approach has been to add heat sinks, fans, and vents. But what if the enclosure itself could be part of the thermal solution?

Reaction injection molding opens up possibilities for thermal management that most engineers overlook. The process allows for material formulations and part geometries that can significantly improve heat dissipation without adding secondary components or assembly steps.

Today's electronic devices generate heat densities that would have seemed impossible a decade ago. A typical industrial control unit might pack 200 watts of heat generation into a space smaller than a shoebox. Military electronics face even tougher requirements, operating in ambient temperatures exceeding 50°C while maintaining internal component temperatures below their critical thresholds.

Traditional injection-molded enclosures act as insulators, trapping heat inside. Metal enclosures conduct heat but add weight and cost while limiting design flexibility. Engineers often find themselves caught between thermal performance requirements and practical constraints around weight, cost, and electromagnetic compatibility.

The RIM process offers unique advantages for thermal management through both material science and design flexibility. Unlike conventional injection molding, RIM can incorporate thermally conductive fillers directly into the polymer matrix without degrading mechanical properties. Testing shows that properly formulated RIM materials can achieve thermal conductivity values up to 1.5 W/mK while maintaining impact strength above 15 kJ/m².

The low-pressure nature of the RIM process means you can mold parts with varying wall thicknesses in the same component. This allows engineers to create thick sections for heat spreading in high-flux areas while maintaining thin walls elsewhere to minimize weight. You can't achieve these dramatic thickness variations with injection molding without creating sink marks or dimensional instability.

Smart thermal design in RIM-molded enclosures starts with understanding heat flow paths. The most effective approach integrates thermal management features directly into the part geometry rather than treating them as add-ons.

Consider a power electronics enclosure we developed for an autonomous vehicle manufacturer. The design incorporated molded-in heat spreading channels that directed thermal energy away from hot spots toward areas with better convective cooling. The channels added minimal weight while improving thermal performance by 35% compared to a flat-wall design.

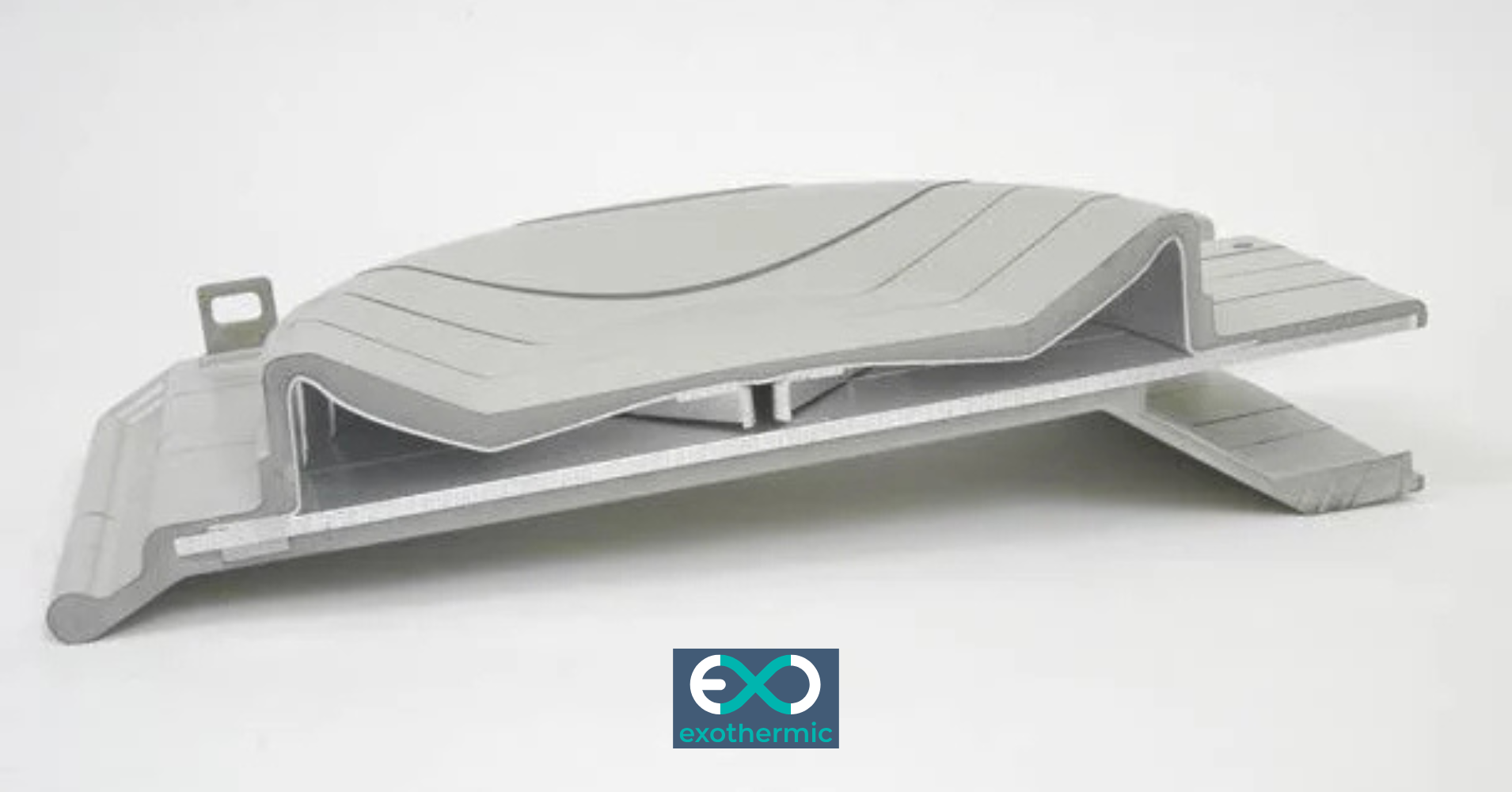

Another powerful technique involves selective material placement. RIM allows for encapsulation of metal inserts precisely where thermal conductivity matters most. A medical imaging system enclosure used aluminum heat spreaders encapsulated at processor mounting points, creating direct thermal paths to the exterior while maintaining complete electrical isolation.

The flexibility of RIM chemistry enables custom formulations targeted at specific thermal requirements. Standard Poly-DCPD formulations provide decent insulation properties for applications where thermal isolation is desired. But for heat dissipation applications, incorporating boron nitride or aluminum oxide fillers can dramatically increase thermal conductivity.

What makes RIM particularly interesting is the ability to achieve high filler loadings without sacrificing processability. We've successfully processed materials with 40% thermally conductive filler content while maintaining the ability to fill complex geometries with wall thicknesses down to 3mm.

The key lies in understanding how filler particle size, shape, and surface treatment affect both thermal and mechanical properties. Platelet-shaped fillers provide better thermal conductivity along their plane but can create anisotropic properties. Spherical fillers offer more predictable behavior but require higher loadings to achieve the same thermal performance.

Laboratory testing only tells part of the story. Real-world thermal performance depends on factors like surface finish, airflow patterns, and thermal cycling behavior. A recent project for a robotics manufacturer demonstrated these complexities.

The initial design achieved excellent steady-state thermal performance in testing, with junction temperatures staying 15°C below specification. However, field testing revealed problems during rapid power cycling. The enclosure's thermal mass was causing temperature lag that triggered protective shutdowns during startup sequences.

The solution required reformulating the material to reduce specific heat capacity while maintaining thermal conductivity. By adjusting the filler system and polymer backbone, we achieved a 30% reduction in thermal time constant without compromising steady-state performance.

While passive thermal management through material selection and geometry optimization can accomplish a lot, many high-power applications still require active cooling. RIM technology excels at integrating features for fans, heat pipes, and liquid cooling systems.

The process allows for precise molding of fan shrouds and air guides that optimize airflow patterns. Complex internal geometries that would require multiple parts in injection molding can be created in a single RIM component. This reduces assembly time and eliminates potential air leaks that reduce cooling efficiency.

For liquid cooling applications, RIM's chemical resistance becomes valuable. Poly-DCPD formulations resist common coolants including glycol-water mixtures and dielectric fluids. The material's low permeability prevents coolant absorption that could lead to dimensional changes or property degradation over time.

The economics of thermal management often get overlooked until late in the design process. RIM tooling costs typically run 60-70% lower than injection molding tools for comparable parts. This cost advantage becomes even more pronounced when you consider the ability to integrate multiple functions into a single part.

A traditional approach might require an injection-molded enclosure, die-cast heat sinks, and stamped metal shields, each with its own tooling and assembly costs. A properly designed RIM part can combine all these functions while providing better thermal performance. For production volumes between 500 and 5,000 units annually, the total cost reduction often exceeds 40%.

Thermal management challenges will only intensify as electronics continue to increase in power density. The convergence of electric vehicles, 5G infrastructure, and edge computing creates demand for enclosures that can handle heat loads previously reserved for data center applications.

Advanced RIM formulations currently in development promise thermal conductivities approaching 5 W/mK while maintaining the mechanical properties and processing advantages that make RIM attractive. Combined with topology optimization software and thermal simulation tools, engineers can create enclosure designs that treat thermal management as an integral design element rather than an afterthought.

The companies that master these techniques will have a significant advantage in markets where thermal performance determines product reliability and lifespan. For engineers willing to move beyond traditional enclosure design thinking, RIM technology offers a path to solving thermal challenges that seemed impossible just a few years ago.

When engineers think about protecting sensitive components or enhancing structural integrity, they...

Marine engineers face a brutal reality when selecting materials for boat interior components....

Most engineers default to mechanical fasteners or adhesives when integrating components into larger...