When You Should Consider Reaction Injection Molding (RIM)

In today's competitive manufacturing landscape, engineers and production managers face mounting...

By: Paul Steck on Aug 14, 2025 8:00:00 AM

Engineering teams face this scenario repeatedly: a complex plastic component with annual volumes around 2,000 units, intricate geometry requirements, and a project timeline that doesn't accommodate 16-week tooling lead times. The reflexive response? Design for injection molding and absorb the economic penalties.

This approach worked when injection molding represented the only viable path for precision plastic parts. However, advances in material science in reaction injection molding have created manufacturing opportunities that many engineers haven't evaluated since their initial training.

Injection molding economics break down rapidly below 5,000 annual units. Steel tooling costs ranging from $150,000 to $400,000 create a fixed cost burden that becomes prohibitive for smaller production runs. For a 1,500-piece production run, tooling costs alone contribute $100-$265 per component before factoring in material or processing expenses.

The processing requirements compound these challenges. Injection molding demands temperatures of 400-500°F and pressures reaching 20,000 psi, necessitating robust steel tooling and high-tonnage presses. These requirements drive both initial investment and ongoing operational costs.

RIM processing operates under fundamentally different parameters. The chemistry processes at approximately 90°F, though the thermoset reaction generates heat that elevates part temperatures to 250°F for polyurethane systems and 350°F for Poly-DCPD during cure cycles. Crucially, higher-density polyurethane RIM materials create mold pressures of only 50-100 psi, while Poly-DCPD's reaction generates zero mold pressure.

These modest processing requirements enable aluminum tooling fabrication, reducing initial tool costs by approximately 50% compared to hardened steel alternatives. The thermal conductivity advantages of aluminum become particularly valuable in RIM applications, where efficient heat removal during the cure cycle directly impacts part quality and cycle time economics.

Modern RIM materials challenge conventional assumptions about thermoset capabilities. Poly-DCPD systems deliver tensile strengths comparable to engineering thermoplastics while offering superior chemical resistance and impact performance. The material exhibits 7-10% lower density than traditional alternatives, contributing to overall weight reduction in finished assemblies.

The low viscosity characteristics of RIM chemistry enable design approaches that injection molding cannot accommodate. Wall thickness variations from 0.125" to over 1.0" within single components become routine rather than exceptional. This design flexibility supports part consolidation strategies that eliminate multiple components and associated assembly operations.

RIM's low-pressure, low-temperature processing environment enables encapsulation techniques that would damage sensitive components in injection molding. RFID chips, batteries, wire harnesses, LCDs, antennas, and other electronic components can be overmolded without thermal or mechanical damage concerns.

The gentle processing conditions also permit the integration of structural elements during molding. Metal inserts, carbon fiber reinforcements, and composite structures can be positioned within the mold cavity and encapsulated during the RIM process, creating hybrid components with performance characteristics exceeding those of homogeneous plastic parts.

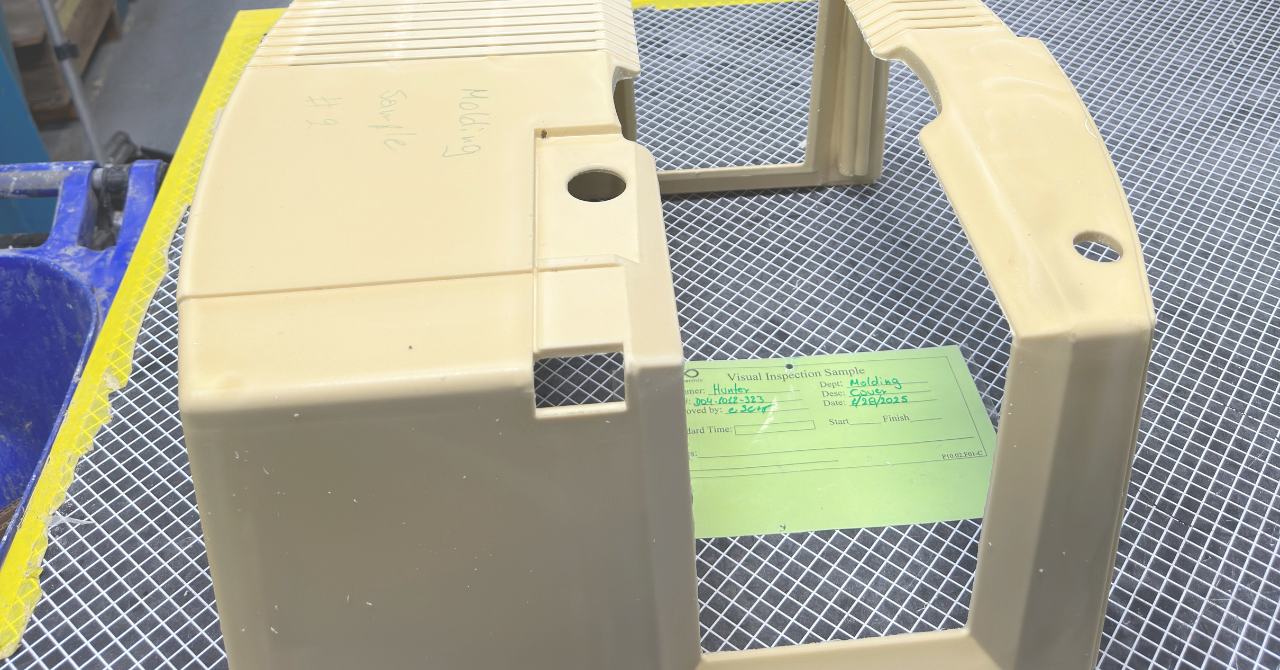

Large component capabilities represent another significant advantage. Parts exceeding several feet in dimension can be produced with consistent wall thickness control and excellent surface finish characteristics. These geometries often prove technically challenging or economically prohibitive using injection molding approaches.

The selection criteria between RIM and injection molding should consider several technical and economic factors. Production volumes below 5,000 annual units generally favor RIM economics, particularly when combined with complex geometries or large part dimensions.

Lead time requirements often drive process selection. RIM aluminum tooling can be fabricated in 4-6 weeks compared to 12-16 weeks for injection molding steel tools. This timeline compression can prove critical for product development schedules or market response requirements.

Design complexity evaluation should include wall thickness variation requirements, encapsulation needs, and surface finish specifications. RIM excels when these factors create challenges for conventional injection molding approaches.

Transitioning to RIM requires partnership with experienced processors who understand both the chemistry and tooling requirements. The aluminum molds used in RIM applications demand different design approaches than steel injection molding tools, particularly regarding cooling system design and surface finish requirements.

Material selection becomes more nuanced with RIM systems. While injection molding offers standardized thermoplastic grades, RIM materials can be formulated for specific application requirements, including flame retardancy, chemical resistance, or electrical insulation properties.

Quality system integration requires understanding RIM-specific inspection and testing protocols. The thermoset nature of RIM materials creates different quality control requirements compared to thermoplastic systems.

Many engineering teams continue defaulting to injection molding because it represents a familiar solution path. However, the economic and technical landscape has shifted significantly, particularly for complex, low-volume applications.

RIM technology now offers proven alternatives that can reduce development costs, compress project timelines, and enable design approaches that injection molding cannot accommodate. The question isn't whether RIM can replace injection molding universally, but rather whether specific applications might benefit from reconsidering fundamental manufacturing assumptions.

For components requiring fewer than 5,000 annual units, complex geometries, or encapsulation capabilities, RIM deserves engineering evaluation alongside traditional injection molding approaches. The economic and technical advantages may prove more compelling than conventional wisdom suggests.

In today's competitive manufacturing landscape, engineers and production managers face mounting...

If you've spent your career designing parts for injection molding, your instincts are well-trained....

Defense contractors face a frustrating math problem. You need 500 ballistic panels. Or 2,000...