When Protection and Production Collide: How RIM Technology Revolutionizes Ballistic Manufacturing

The intersection of ballistic protection and manufacturing efficiency has always presented a...

By: Paul Steck on Jun 3, 2025 8:00:01 AM

When engineers think about protecting sensitive components or enhancing structural integrity, they often default to housings, brackets, or separate protective assemblies. But what if the manufacturing process itself could seamlessly integrate protection directly into the part design?

This is where encapsulation through Reaction Injection Molding transforms both component protection and manufacturing efficiency.

Unlike traditional molding processes that operate under extreme pressures and temperatures, RIM's low-pressure environment (typically 50-150 psi) and moderate processing temperatures (90-105°F) create ideal conditions for embedding sensitive materials without damage. The low-viscosity polyurethane components flow around encapsulated items with remarkable precision, creating a permanent bond that eliminates the need for secondary assembly operations.

This process fundamentally changes how engineers approach the integration of components. Rather than designing separate protective measures, the encapsulation becomes an integral part of the manufacturing solution.

Metal Reinforcements: Steel plates, aluminum extrusions, and custom-formed metal structures integrate seamlessly into RIM parts, providing a robust foundation for enhanced performance. A laboratory centrifuge manufacturer recently encapsulated an aluminum and steel internal framework to achieve the structural rigidity required for high-speed operation while maintaining the lightweight properties and cosmetic finish that polyurethane provides. The metal structure handles the mechanical loads while the RIM material provides environmental protection and aesthetic appeal.

Electronic Components: Circuit boards, sensors, and wiring harnesses can be embedded entirely within the RIM structure. This approach protects proprietary electronics from reverse engineering while providing permanent environmental sealing. Medical device manufacturers often encapsulate control electronics to meet IP65 sealing requirements without the need for additional gaskets or housings.

Composite Reinforcements: Carbon fiber sheets, glass fiber mats, and specialized textiles become integral structural elements. The RIM process allows for selective reinforcement placement, putting strength exactly where mechanical analysis indicates it's needed rather than uniformly throughout the part.

Threaded Inserts and Hardware: Standard threaded inserts, captive fasteners, and specialized hardware embed directly into the part during molding. This eliminates post-molding installation while creating stronger attachment points than those achieved through secondary operations.

In aerospace applications, manufacturers encapsulate lightweight honeycomb cores with polyurethane to create structural panels that meet stringent weight requirements while providing exceptional impact resistance. The RIM process bonds completely to the core material, creating a monolithic structure that outperforms mechanically assembled alternatives.

Industrial equipment manufacturers often encapsulate magnet assemblies for use in sensor applications. The polyurethane provides complete environmental protection while maintaining the precise magnetic field characteristics required for accurate sensing. Traditional protective housings often interfere with magnetic performance, but encapsulation eliminates this concern.

For outdoor equipment applications, manufacturers encapsulate stainless steel mounting brackets and hardware during the molding process. This approach provides superior corrosion protection compared to coated hardware while eliminating the labor and potential failure points associated with assembled systems.

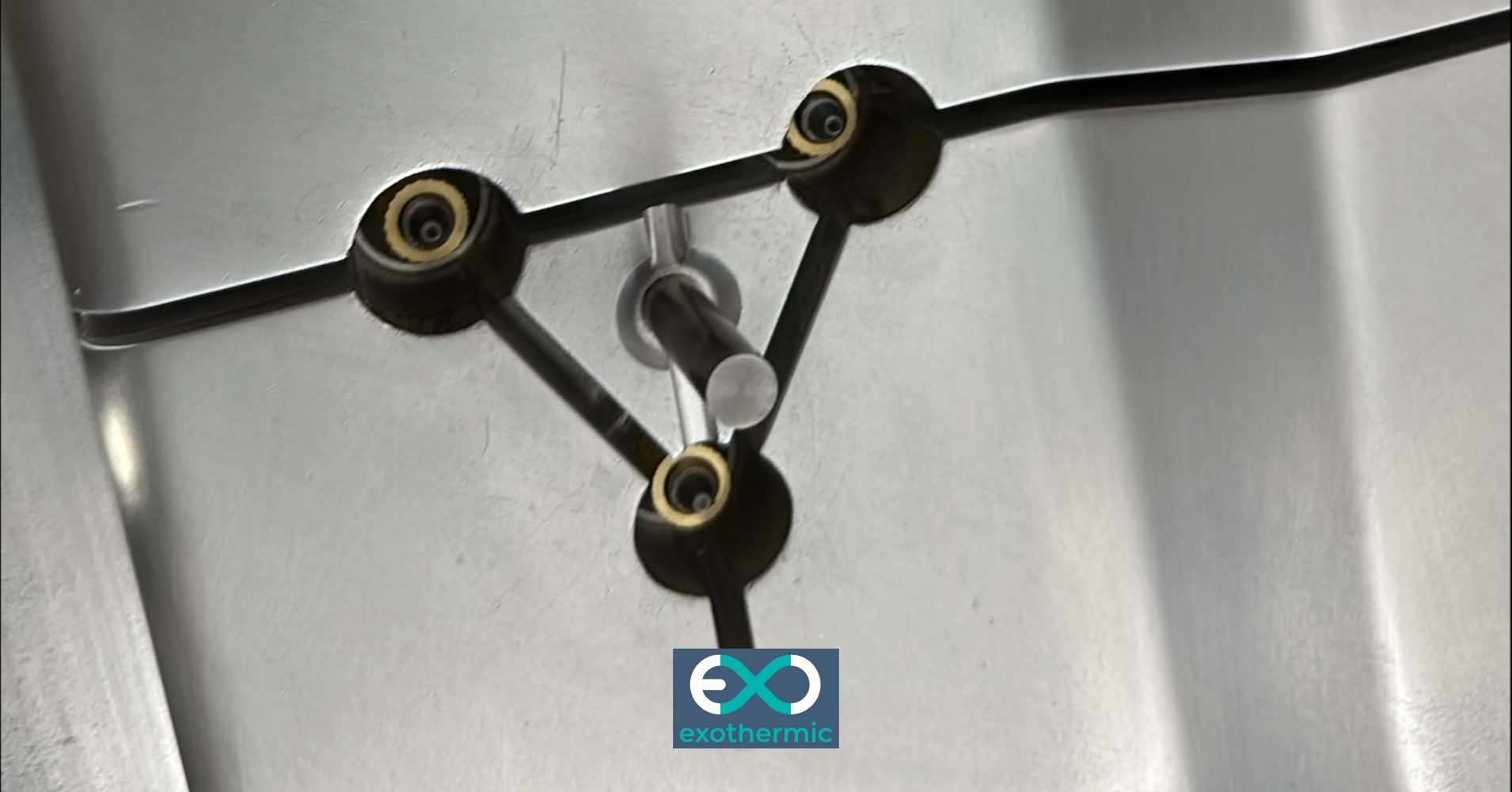

See photos below for inserts in the mold and then the finished molded part.

The coefficient of thermal expansion between the encapsulated material and the polyurethane requires careful consideration. Metal components expand and contract differently from polyurethane, and successful encapsulation design accounts for these differences to prevent stress concentration or bond failure over temperature cycles.

Component placement during molding demands precision. The RIM process offers excellent repeatability; however, the initial tooling design must account for component positioning and retention during the injection process. Experienced RIM manufacturers develop specialized fixtures and techniques to ensure consistent placement across production runs.

Surface preparation of encapsulated components significantly affects bond strength. Clean, properly prepared surfaces create mechanical and chemical bonds that often exceed the strength of the surrounding polyurethane material. This preparation becomes critical for components subject to high mechanical loads or thermal cycling.

Encapsulation through RIM transforms multiple manufacturing steps into a single operation. Parts that previously required fabrication, assembly, sealing, and finishing now emerge from the mold as complete, functional components. This consolidation reduces inventory, eliminates assembly errors, and significantly shortens production timelines.

The ability to encapsulate components opens new possibilities for product design. Engineers can optimize designs for performance rather than manufacturability constraints, knowing that complex internal structures can be integrated during the molding process rather than assembled afterward.

For manufacturers seeking design freedom combined with manufacturing efficiency, RIM encapsulation represents a proven approach to creating sophisticated components that would be difficult or impossible to produce through conventional methods. The process transforms component protection from an afterthought into an integral part of the manufacturing solution.

Contact us to determine if RIM encapsulation is suitable for your parts.

The intersection of ballistic protection and manufacturing efficiency has always presented a...

Engineers face a persistent challenge: how do you protect sensitive components without compromising...

Heat kills performance. Every engineer knows this fundamental truth, yet thermal management often...