Engineering Marine Equipment Enclosures: Why Poly-DCPD Reigns Supreme in Saltwater Environments

Marine engineers face a brutal reality when selecting materials for boat interior components....

When selecting materials for critical applications, engineers often confuse ductility with flexibility. This misunderstanding can lead to material choices that compromise performance, increase warranty claims, or result in catastrophic failures. For engineers evaluating alternatives to traditional thermoplastics or metals, understanding how Poly-DCPD RIM molded parts deliver exceptional ductile properties becomes essential for making informed material decisions.

Ductility refers to a material's ability to undergo permanent deformation under tensile stress before fracture. A ductile material can absorb significant energy through plastic deformation, making it resistant to sudden, brittle failures. When stress exceeds the elastic limit, ductile materials yield gradually, providing visible warning signs before ultimate failure.

Flexibility describes a material's ability to bend repeatedly without breaking, typically within its elastic range. Flexible materials return to their original shape when the applied force is removed. While flexibility indicates good fatigue resistance under cyclic loading, it doesn't necessarily predict how a material will behave under extreme stress conditions.

The distinction matters because ductile materials provide safety margins through controlled failure modes, while flexible materials excel in applications requiring repeated deflection without permanent deformation.

Conventional thermoplastics often sacrifice ductility for other properties. Glass-filled nylon, while strong and stiff, tends toward brittle failure modes that can be catastrophic in critical applications. Polycarbonate offers some ductility but lacks chemical resistance and high-temperature performance. Traditional metals provide excellent ductility but add weight, corrosion concerns, and manufacturing complexity.

Thermoset materials have historically been even more limited. Standard epoxies and polyesters cure into rigid, brittle matrices that crack under stress rather than yielding. This brittleness becomes particularly problematic in applications experiencing impact loads, thermal cycling, or vibration.

Poly-DCPD (polydicyclopentadiene) represents a breakthrough in thermoset technology, delivering ductile behavior typically associated with metals while maintaining the processing advantages of RIM molding. The material achieves this through its unique molecular structure and crosslinking density.

During the RIM process, DCPD monomers undergo ring-opening metathesis polymerization, creating long polymer chains with controlled crosslinking. This structure allows for energy absorption through molecular chain movement and controlled plastic deformation. Unlike highly crosslinked thermosets that fracture brittlely, Poly-DCPD can yield and flow under stress.

The resulting material exhibits tensile elongation values typically ranging from 15-25%, compared to 2-5% for conventional thermosets. This elongation capacity translates directly into improved impact resistance and damage tolerance in real-world applications.

Impact Resistance: Poly-DCPD's ductile nature allows it to absorb impact energy through plastic deformation rather than fracturing. Testing shows impact strengths often exceeding 200 ft-lb/in compared to 1-3 ft-lb/in for standard epoxies. This performance prevents catastrophic failures in applications like protective housings or structural components.

Fatigue Performance: The material's ability to yield slightly under repeated loading prevents crack initiation and propagation. Components experience gradual wear rather than sudden failure, improving reliability in cyclic loading applications.

Thermal Stress Management: Ductile behavior helps accommodate thermal expansion and contraction cycles. Rather than developing stress cracks, Poly-DCPD components can yield slightly to relieve thermal stresses, extending service life in temperature-varying environments.

Damage Tolerance: When overloaded, ductile materials provide visible warning through permanent deformation before complete failure. This behavior allows for inspection and replacement before catastrophic failure occurs.

Choose Poly-DCPD for ductile applications when your design requires:

Components that must survive impact loading without brittle failure. The material's energy absorption capacity prevents sudden fractures that could compromise system integrity.

Parts experiencing thermal cycling or thermal shock. The ductile response accommodates thermal stresses that would crack brittle materials.

Structural elements where gradual yielding is preferable to sudden failure. This controlled failure mode provides safety margins and inspection opportunities.

Applications requiring both chemical resistance and ductile behavior. Unlike metals that corrode or thermoplastics that stress crack, Poly-DCPD maintains ductile properties in harsh chemical environments.

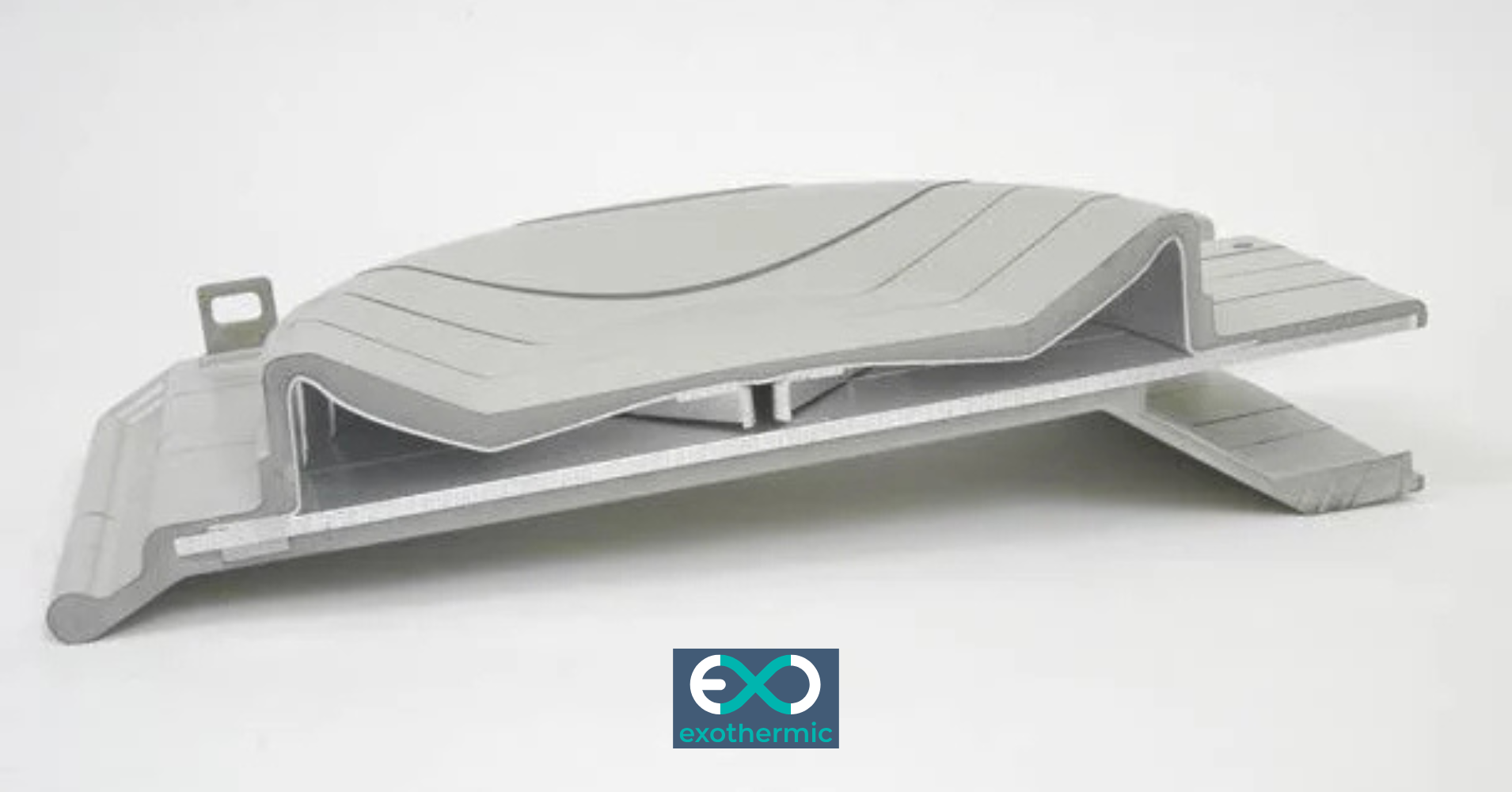

The RIM process enables Poly-DCPD to achieve optimal ductile properties through precise control of curing conditions. Low-pressure molding prevents internal stresses that could reduce ductility. Controlled temperature profiles ensure complete polymerization while maintaining the molecular structure necessary for ductile behavior.

Variable wall thickness capability allows engineers to optimize ductility where needed while maintaining structural efficiency. Thick sections can provide maximum energy absorption, while thinner areas offer weight savings without compromising overall performance.

Encapsulation capabilities enable the combination of ductile polymer properties with metal reinforcements, creating hybrid components that leverage both materials' advantages.

Field testing demonstrates Poly-DCPD's ductile advantages across demanding applications. Aerospace components show improved damage tolerance compared to brittle thermosets. Military equipment benefits from impact resistance that prevents mission-critical failures. Industrial enclosures maintain integrity under mechanical abuse that would shatter conventional housings.

Laboratory testing confirms these field observations. Charpy impact testing reveals energy absorption values 50-100 times higher than conventional thermosets. Tensile testing shows controlled yielding behavior rather than brittle fracture. Dynamic mechanical analysis confirms the material maintains ductile properties across wide temperature ranges.

Maximizing ductile benefits requires thoughtful design approaches. Avoid sharp corners and stress concentrations that can initiate brittle failures even in ductile materials. Consider gradual section transitions that allow stress redistribution through plastic deformation.

Material thickness directly influences ductile behavior. Thicker sections provide more material for energy absorption but may compromise other design requirements. Work with experienced RIM processors to optimize geometry for your specific ductility requirements.

Surface treatments and environmental exposure can affect ductile properties. UV exposure may degrade surface layers, while chemical exposure could alter the polymer structure. Design appropriate protection strategies to maintain long-term ductile performance.

When evaluating Poly-DCPD against current materials, consider total system performance rather than individual properties. While the material may cost more per pound than commodity thermoplastics, its ductile properties often eliminate the need for additional reinforcement, impact protection, or safety margins.

Calculate the value of damage tolerance in your application. How much does a brittle failure cost in warranty claims, downtime, or safety incidents? Ductile materials that provide controlled failure modes often justify higher initial costs through reduced lifecycle expenses.

Consider manufacturing efficiency gains. RIM processing allows complex geometries and part consolidation that may offset material cost differences. The ability to mold large, integrated components can eliminate assembly steps and potential failure points.

Understanding the distinction between ductility and flexibility enables better material decisions for critical applications. Poly-DCPD RIM molding delivers engineered ductility that provides safety margins, damage tolerance, and reliable performance in demanding environments. For engineers seeking alternatives to brittle thermosets or corrosion-prone metals, this material technology offers compelling advantages worth serious evaluation.

Marine engineers face a brutal reality when selecting materials for boat interior components....

What Industries and Applications are P-DCPD Parts Suitable For?

In today's climate-conscious world, manufacturers are increasingly seeking sustainable alternatives...