What Design Firms Need to Know About Designing Parts for Reaction Injection Molding

When industrial designers evaluate manufacturing processes, they're often caught between competing...

By: Paul Steck on Nov 4, 2025 1:22:19 PM

When engineering teams face the challenge of producing large plastic parts at low to medium volumes, the decision between Reaction Injection Molding (RIM) and thermoforming can significantly impact project success. Both processes excel at creating substantial components, yet their fundamental differences in capabilities, costs, and design flexibility make process selection critical for achieving optimal results.

The fundamental distinction between RIM and thermoforming lies in their approach to part creation. RIM combines two liquid polyurethane components that react and cure inside a closed mold at low pressure (50-150 psi) and low temperature (90-105°F). This chemical reaction creates a thermoset material that forms to precise specifications within the mold cavity. Thermoforming, conversely, heats thermoplastic sheets until pliable, then forms them over or into a mold using vacuum or pressure. This sheet-forming process inherently limits design complexity while offering specific advantages for simpler geometries.

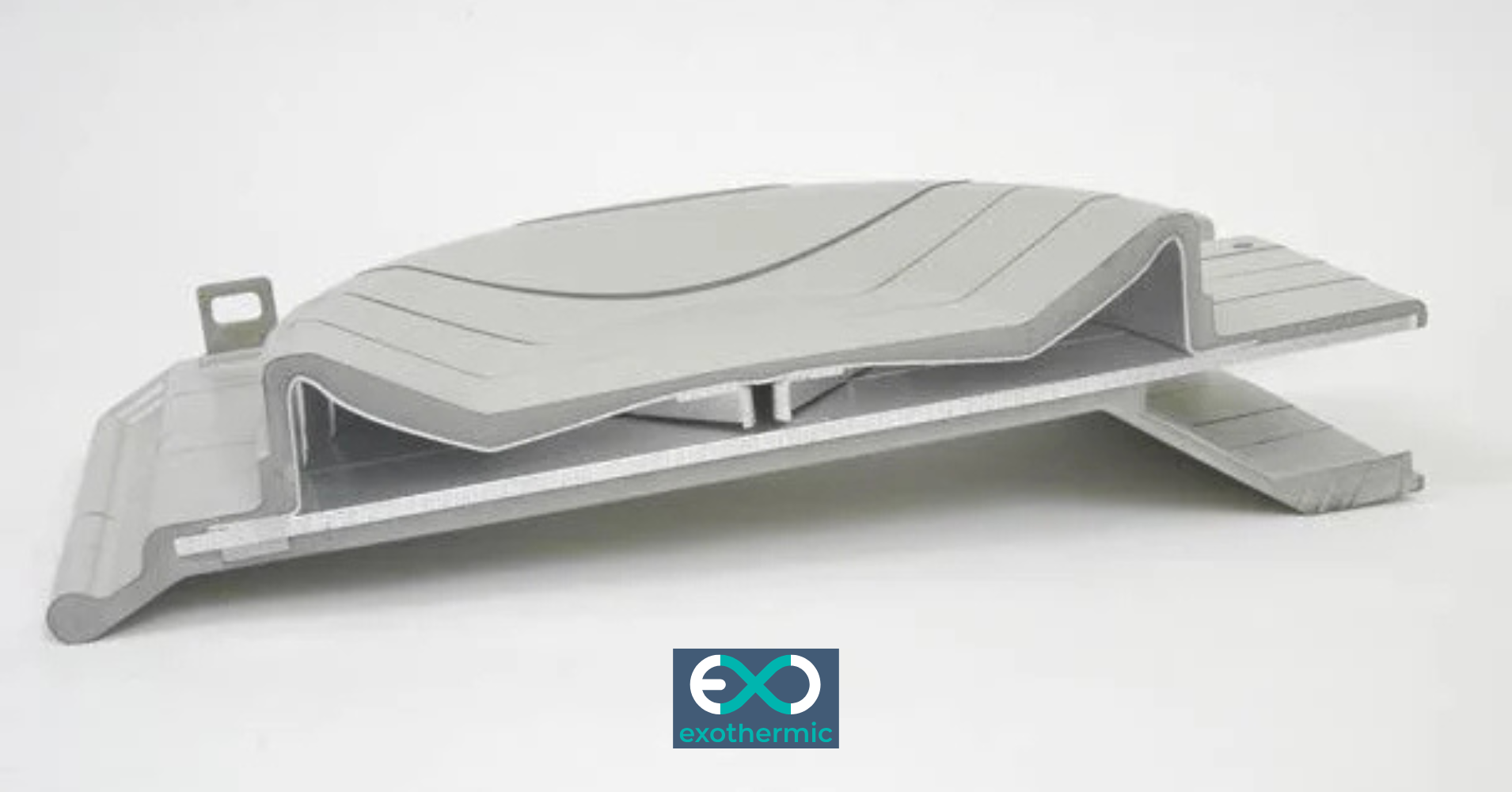

These process differences translate directly into practical manufacturing considerations. RIM operates with liquid materials that flow into every detail of the mold, enabling complex internal features and variable wall thicknesses ranging from 0.125" to 1.125" within the same part. Thermoforming's sheet-based approach restricts parts to relatively uniform wall thickness, with any internal features requiring secondary bonding operations that increase assembly time and introduce potential failure points.

The design freedom offered by each process often determines the optimal choice for specific applications. RIM molding excels when part designs require molded-in stiffening ribs, internal features, or significant wall thickness variations. Consider a medical instrument housing that needs internal mounting bosses, cable management features, and varying wall thickness for optimal weight distribution. RIM can incorporate all these elements directly into the mold, producing a complete part in a single operation.

Thermoforming works best for parts with predominantly external features and uniform wall thickness. A equipment cover with simple contours and consistent wall thickness represents an ideal thermoforming application. However, when that same cover requires internal mounting points, stiffening ribs, or integrated cable channels, the process quickly becomes less practical. Each internal feature demands manual attachment after forming, multiplying labor costs and extending lead times while introducing dimensional variation at every assembly point.

The encapsulation capability unique to RIM provides another critical design advantage. The low-pressure, low-temperature process allows safe encapsulation of sensitive electronics, printed circuit boards, antennas, and structural metal inserts without damage. This capability enables engineers to create sophisticated assemblies that combine protection, enhanced mass distribution, and improved electromagnetic shielding in a single molded part. Thermoforming's high heat requirements make component encapsulation impossible, limiting design options for integrated electronic assemblies.

The economic crossover point between RIM and thermoforming depends on multiple factors beyond simple per-part costs. For production volumes between 100 and 5,000 parts annually, both processes remain viable, but total cost analysis must include tooling, labor, and assembly considerations.

RIM tooling, typically machined from aluminum, costs significantly less than steel injection molding tools while offering greater durability than thermoforming molds. Initial RIM tooling investment ranges from 40% to 60% less than comparable thermoplastic injection molds. More importantly, aluminum RIM tools accommodate design changes at substantially lower cost than modifying thermoforming tools or creating new forming fixtures for added features.

The unit cost comparison shifts based on part complexity. Simple thermoformed parts without secondary operations can achieve lower piece prices than RIM parts at similar volumes. However, once manual assembly enters the equation, RIM's ability to consolidate features often results in lower total manufactured cost. A complex enclosure requiring 12 bonded internal features might cost $45 to thermoform and assemble, while the same part produced via RIM with all features molded in place could cost $38 complete.

Labor intensity represents another economic factor favoring RIM for complex parts. Thermoforming's secondary bonding operations require skilled manual labor, introducing variability and quality concerns. Each bonded component adds inspection requirements and potential rework costs. RIM's single-step process eliminates these variables, delivering consistent part-to-part repeatability essential for medical devices, aerospace components, and precision instrumentation.

Both processes accommodate various finishing options, though with different baseline capabilities. Thermoformed parts retain the surface quality of the original sheet material, which can range from high-gloss to textured finishes. This inherent finish quality suits applications where the sheet manufacturer's surface meets requirements without additional processing.

RIM parts emerge from the mold with excellent surface definition that readily accepts paint, silk screening, and other surface treatments. The process achieves automotive-grade Class A painted surfaces when properly prepared, enabling brand enhancement through custom colors, textures, and graphics. The dimensional stability of RIM parts ensures consistent paint thickness and appearance across production runs, critical for maintaining brand standards in consumer-facing products.

Surface modification requirements can shift the economic balance between processes. Thermoformed parts requiring extensive surface preparation for painting may lose their cost advantage over RIM parts that paint readily with minimal preparation. Similarly, products requiring precise logo placement or multi-color decoration benefit from RIM's dimensional consistency and surface predictability.

The thermoset polyurethane chemistry of RIM offers extensive material customization impossible with thermoforming's fixed sheet properties. Engineering teams can specify RIM formulations optimized for impact resistance, chemical compatibility, temperature stability, or fire retardancy based on application requirements. Structural composite RIM systems incorporating glass or carbon fiber deliver exceptional stiffness-to-weight ratios for demanding applications.

Thermoforming materials, while diverse, come with predetermined properties that cannot be modified during processing. Sheet selection locks in performance characteristics, potentially requiring over-specification to meet all requirements. A part needing both chemical resistance and impact strength might require an expensive specialty sheet, while RIM could achieve these properties through appropriate formulation at lower material cost.

The structural integrity comparison favors RIM for load-bearing applications. Thermoformed parts rely entirely on their outer shell for strength, making them susceptible to "tin canning" or deformation under load. RIM parts with molded-in ribs and optimized wall thickness distribution provide superior stiffness without the weight penalty of uniformly thick thermoformed sheets. This structural efficiency becomes critical in transportation applications where weight reduction directly impacts fuel efficiency or payload capacity.

The decision matrix for selecting between RIM and thermoforming should prioritize your specific application requirements. Choose RIM when your application demands complex internal geometry, variable wall thickness for weight optimization, component encapsulation capabilities, tight dimensional tolerances with part-to-part repeatability, structural optimization through integrated stiffening features, custom material properties for specific performance requirements, or production volumes between 100 and 5,000 parts annually with potential design iterations.

Consider thermoforming when your design consists of simple external geometries with uniform wall thickness, surface aesthetics of available sheet materials meet requirements without painting, production volumes remain very low (under 100 parts) with stable designs, minimal assembly or secondary operations are acceptable, or the fastest possible tooling turnaround outweighs other considerations.

The total cost evaluation must extend beyond simple part pricing to encompass tooling investment and modification costs, assembly labor and associated quality risks, inventory carrying costs for different production strategies, and lifecycle costs including warranty and field failure rates. RIM's design flexibility often enables part consolidation that eliminates assembly operations, reducing total system cost despite potentially higher individual part prices. The ability to modify aluminum RIM tooling cost-effectively protects against market-driven design changes, particularly valuable during product launch phases.

Quality requirements can definitively favor one process over another. Medical devices requiring validated dimensional consistency, aerospace components demanding predictable material properties, or electronic enclosures needing precise EMI shielding all benefit from RIM's controlled process and material customization capabilities. Conversely, simple protective covers or decorative panels without critical performance requirements might achieve adequate quality through thermoforming at lower cost.

Beyond process capabilities and economics, the level of engineering support available from your manufacturing partner significantly impacts project success. RIM molding suppliers typically offer comprehensive design for manufacturability (DFM) consultation, helping optimize part design for the process while maintaining functional requirements. This collaborative approach during design development prevents costly tooling modifications and ensures manufacturable designs from project inception.

The complexity of RIM chemistry and processing demands experienced technical support that extends beyond simple part production. Material selection guidance, process optimization for specific applications, and troubleshooting expertise distinguish capable RIM partners from basic service providers. Thermoforming's relative simplicity requires less technical depth, though experienced operators still provide valuable input on sheet selection and forming limitations.

The evolution of manufacturing technology continues to expand possibilities for both processes. Advanced RIM formulations like Poly-DCPD resin systems push the boundaries of material performance, opening new applications in demanding industries. Thermoforming advances focus on automation and process control, potentially reducing labor content for secondary operations.

For manufacturers evaluating these technologies today, the fundamental trade-offs remain consistent. RIM delivers unmatched design freedom and part consolidation opportunities at competitive costs for low to medium volumes. Thermoforming provides economical solutions for simpler parts where its limitations align with design requirements. Understanding these distinctions enables informed decisions that optimize product performance, manufacturing efficiency, and total program cost.

The key to successful process selection lies in early evaluation of design requirements against process capabilities. Engaging with experienced RIM and thermoforming suppliers during concept development ensures designs leverage each process's strengths while avoiding costly compromises. Whether your application demands the design sophistication of RIM or the simplicity of thermoforming, matching process capabilities to product requirements remains the foundation of manufacturing success.

When industrial designers evaluate manufacturing processes, they're often caught between competing...

When manufacturers look at cost, they often make a critical mistake: they focus almost exclusively...

Most companies discover design improvements after their first production run. A feature needs...