Case Study

Tile-Redi

Affordable Tooling, Along with the Combination of

Light Weight Material and Significant Wall

Strength, Make RIM the Only Feasible Choice

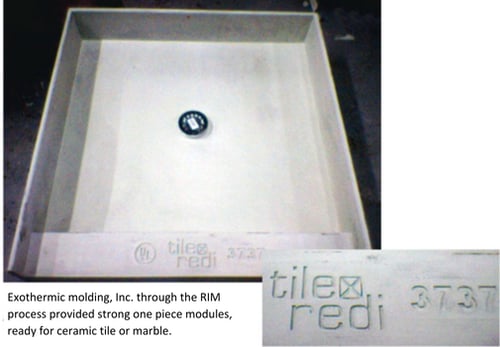

The makers of Tile-Redi Shower Modules had a revolutionary idea. This new concept in shower pan liners, an easy to install one-piece module, is a cost saving replacement for painstaking conventional felt/vinyl/mud installation for shower stalls. Tile-Redi allows contractors to save a great deal of money during the installation process by eliminating the need to spend time and labor forming the shower floor to a waterproof true pitch. The remarkably strong one-piece modules are instantly ready to accept ceramic tile or marble. An added advantage is a lifetime warranty against leaks

When Tile-Redi decided to manufacture their new product, they turned to Exothermic Molding and the RIM process. The 37” x 37” one-piece module is ideally suited for RIM. The relatively large piece is very strong with wall thicknesses up to 1.25” (not possible with other processes), yet light weight with a material density of under 25 pounds per cubic foot. Thick, non-ribbed walls allow heavy loading capability without deflection. The PVC drain section of the module is encapsulated, allowing Tile-Redi to offer a lifetime warranty against leakage.

Half-inch nominal walls match up exactly with the waterproof wallboard used in construction, further simplifying the installation process. A fire retardant paint is applied by Exothermic Molding around the drain on the underside of the Redi-Tile module to pass flammability requirements. The part passes all domestic UL and Canadian building codes.

The hybrid cast aluminum mold, which combines both cast and machined surfaces, cost a modest $15,000. By contrast, in thermoplasric structural foam the mold would cost a minimum of $80,000, possibly much more. An injection mold could cost as much as $150,000.

Three other sizes, a 37” x 37” corner unit, a 37” x 48” and 33” x 60”, are under development.

The benefits of reaction injection molding include:

-

Large, sculpted parts can be molded economically.

-

Variable thickness walls within the same mold allow for greater design freedom.

-

Wall thickness may range from .125 to 1.125 inches.

-

Closed molds produce accurately molded and structurally strong parts.

- Lower tooling cost and shorter tooling lead time.

-

A wide variety of material properties including UL94VO.

-

Electronic components, metal parts, glass and other materials are easily encapsulated.

-

RIM parts are lower cost than the same parts made from metal or fiberglass.

-

Compared to fiberglass, RIM parts have improved repeatability.

-

Composites - RIM parts can be reinforced with many materials.

Exothermic Molding capabilities:

-

CAD Engineering Review

-

Mold Design

-

Mold Manufacture

-

Mold Repair/ Modification

-

RIM Molding

-

Precision Painting

-

Silk Screening

-

Assembly